<><>

<><>A new high-performance wire scanner fork that the latest generation of free electron lasers (FELs) can use for measuring beam profiles has been developed by UK-based firm UHV Design. Produced using technology licensed from the Paul Scherrer Institute (PSI) in Switzerland, the device could be customized for different FELs and low emittance accelerators around the world. It builds on the company’s PLSM range, which allows heavy objects to be moved very smoothly and with minimal vibrations.

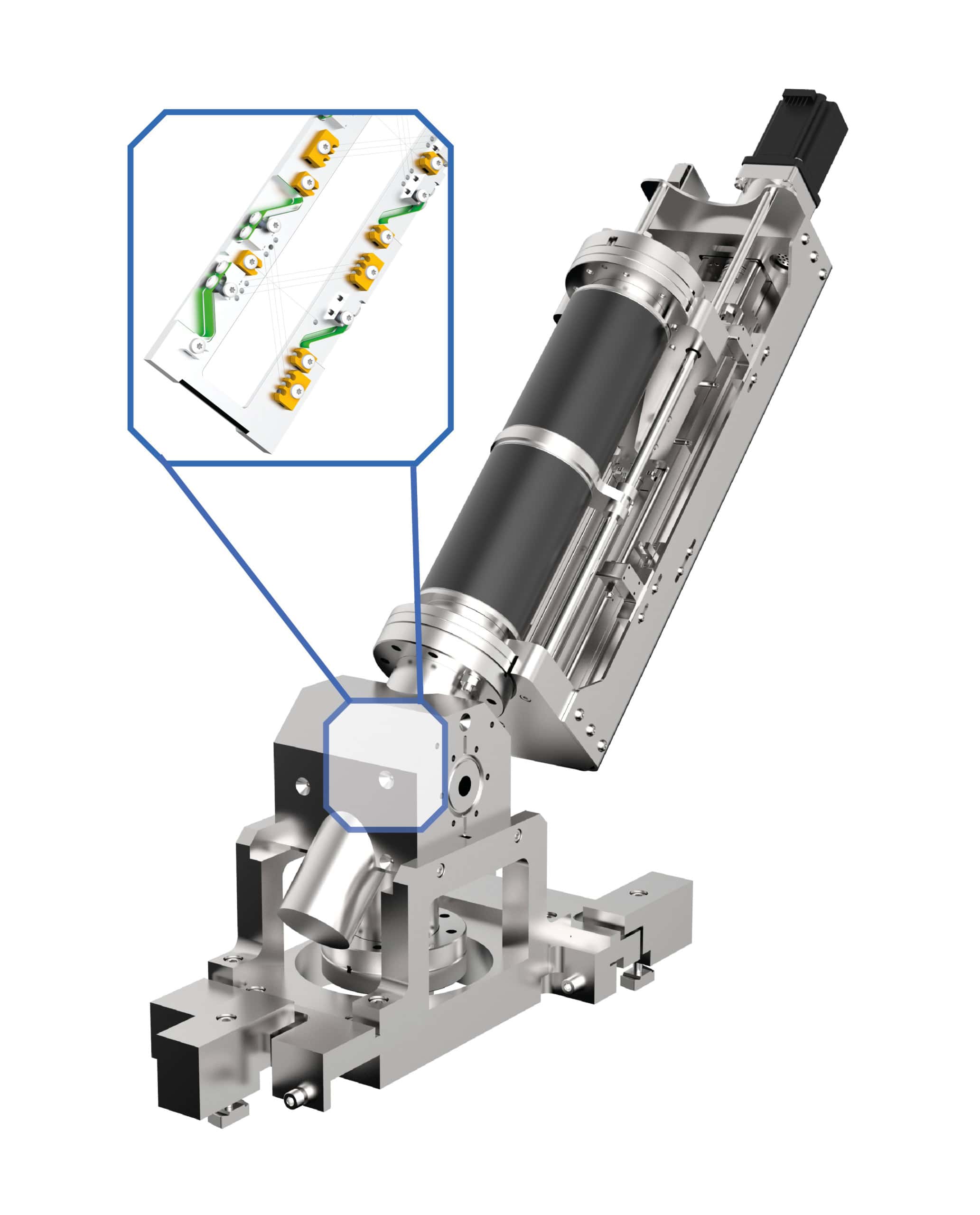

The project began 10 years ago when the PSI was starting to build the Swiss Free Electron Laser and equipping the facility, explains Jonty Eyres. The remit for UHV Design was to provide a stiff, very smooth, bellows sealed, ultra-high vacuum compatible linear actuator that could move a wire fork without vibrating it adversely. The fork, designed by PSI, can hold wires in two directions and can therefore scan the intensity of the beam profile in both X and Y planes using just one device as opposed to two or more as in previous such structures.

“We decided to employ an industrial integrated ball screw and linear slide assembly with a very stiff frame around it, the construction of which provides the support and super smooth motion,” he says. “This type of structure is generally not used in the ultra-high vacuum industry.”

The position of the wire fork is determined through a (radiation-hard) side mounted linear optical encoder in conjunction with the PSI’s own motor and gearbox assembly. A power off brake is also incorporated to avoid any issues with back driving under vacuum load if electrical power was to be lost to the PLSM. All electrical connections terminated with UTO style connectors to PSI specification.

Long term reliability was important to avoid costly and unnecessary down time, particularly between planned FEL maintenance shutdowns. The industrial ball screw and slide assembly by design was the perfect choice in conjunction with a bellows assembly rated for 500,000 cycles with an option to increase to 1 million cycles.

Eyres and his UHV design team began by building a prototype that the PSI tested themselves with a high-speed camera. Once validated, the UHV engineers then built a batch of 20 identical units to prove that the device could be replicated in terms of constraints and tolerances.

The real challenge in constructing this device, says Eyres, was about trying to minimize the amount of vibration on the wire, which, for PSI, is typically between 5 and 25 microns thick. This is only possible if the vibration of the wire during a scan is low compared to the cross section of the wire – that is, about a micron for a 25-micron wire. “Otherwise, you are just measuring noise,” explains Eyres. “The small vibration we achieved can be corrected for in calculations, so providing an accurate value for the beam profile intensity.”

UHV Design holds the intellectual property rights for the linear actuator and PSI the property rights of the fork. Following the success of the project and a subsequent agreement between them both, it was recently decided that UHV Design buy the licence to promote the wire fork, allowing the company to sell the device or a version of it to any institution or company operating a FEL or low-emittance accelerator. “The device is customizable and can be adapted to different types of fork, wires, motors or encoders,” says Eyres. “The heart of the design remains the same: a very stiff structure and its integrated ball screw and linear slide assembly. But, it can be tailored to meet the requirements of different beam lines in terms of stroke size, specific wiring and the components employed.”

UHV Design’s linear actuator was installed on the Swiss FEL in 2016 and has been performing very well since, says Eyres.

A final and important point to note, he adds, is that UHV Design built an identical copy of their actuator when we took on board the licence agreement, so that we could prove it could still reproduce the same performance. “We built an exact copy of the wire scanner, including the PSI fork assembly and sent it to the PSI, who then used the very same high-speed camera rig that they’d employed in 2015 to directly compare the new actuator with the original ones supplied. They reported that the results were indeed comparable, meaning that if fitted to the Swiss FEL today, it would perform in the same way.”

For more information: https://www.uhvdesign.com/products/linear-actuators/wire-scanner/

The post A low vibration wire scanner fork for free electron lasers appeared first on Physics World.