On September 16, the World Economic Forum (WEF) announced its latest batch of “Lighthouse Factories,” with a total of 12 new factories worldwide making the list. Tongwei Solar Meishan Company is the only factory from the global photovoltaic (PV) industry to be selected in this round, marking the birth of the world’s first “Lighthouse Factory” in the field of PV cell manufacturing. This not only makes it the first “Lighthouse Factory” among local enterprises in Sichuan Province, but also signifies that China’s PV industry continues to lead the world in intelligent manufacturing and digital transformation.

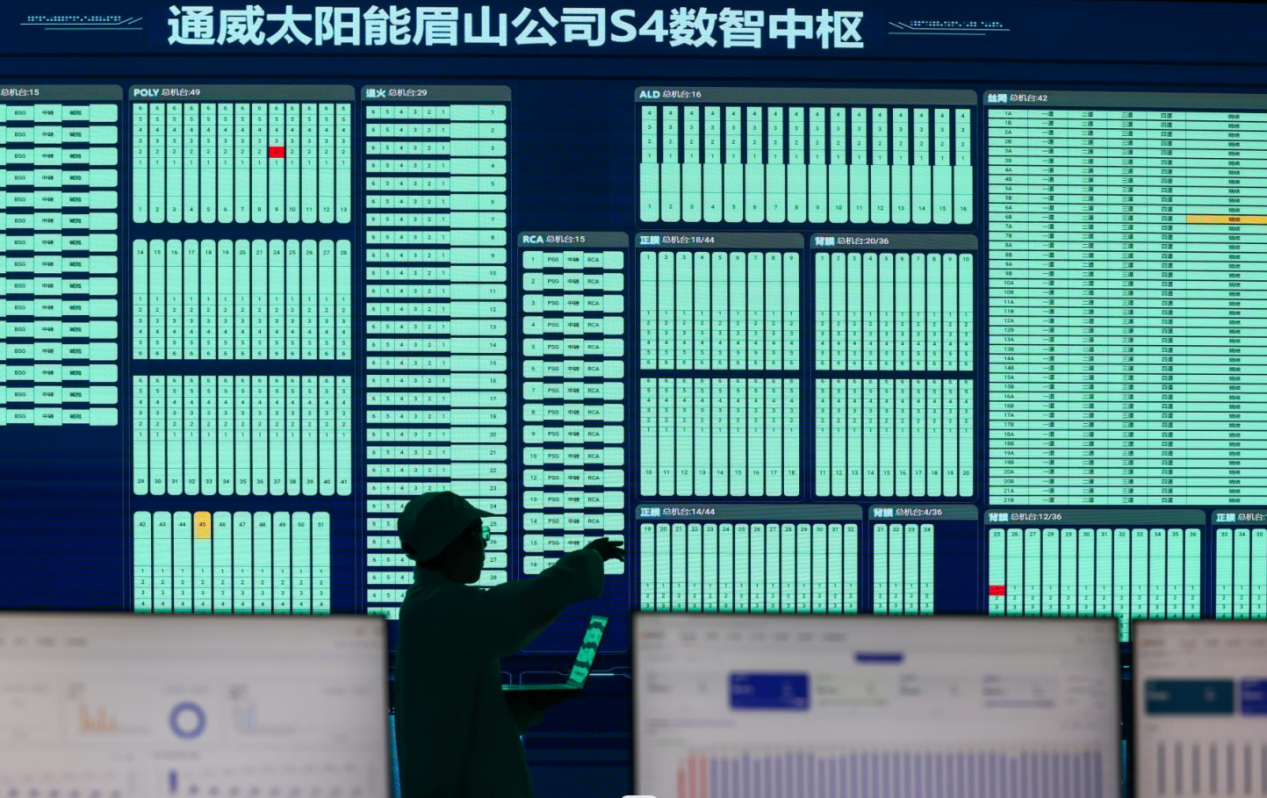

The world’s first Lighthouse Factory in PV cell manufacturing: Tongwei Solar Meishan Company’s intelligent manufacturing workshop

The “Lighthouse Factory” list is jointly selected by the World Economic Forum and McKinsey, aiming to recognize advanced manufacturing models that excel in productivity, supply chain resilience, sustainability, talent development, and customer-centricity. To date, 201 factories worldwide have received this certification, with over 40% of them located in China. Tongwei Solar Meishan Company is the only case among them focusing on PV cell manufacturing. This honor not only affirms Tongwei’s innovative efforts in intelligent manufacturing, but also provides a replicable and scalable transformation model for the global PV industry.

Over 50 Application Practices, Setting a New Benchmark for Intelligent PV Cell Manufacturing

Known as “the world’s most advanced factories,” the requirements for being selected as a “Lighthouse Factory” are extremely stringent, demanding the integration of at least five world-class, leading-edge technology applications. As a demonstrator of “digital manufacturing” and “Industry 4.0,” Tongwei Solar Meishan Company has achieved breakthrough results in power conversion efficiency, process stability, and sustainability through more than 50 Fourth Industrial Revolution (4IR) application scenarios.

Among them, digitalization use cases selected for the “Lighthouse Factory” include: billion-level big data analytics driving solar cell efficiency optimization; deep learning models enabling self-regulating optimization in screen printing; CNN/DNN-powered intelligent coating optimization and closed-loop control; RAG-enhanced GenAI for equipment maintenance and OEE management; and closed-loop quality management based on ResNet and XGBoost models.

The world’s first Lighthouse Factory in photovoltaic cell manufacturing—Tongwei Solar Meishan S4 Digital Intelligence Center

AsianFin -- Tongwei Solar Meishan Company has been recognized as the world’s first “Lighthouse Factory” in the photovoltaic (PV) sector, the World Economic Forum (WEF) announced on Tuesday.

Among 12 new manufacturing sites worldwide selected for excellence in innovation, productivity, and sustainability, Tongwei Solar Meishan stands out for its advanced smart manufacturing capabilities, highlighting China’s leadership in digital transformation and intelligent production in the PV industry.

The Lighthouse Factory designation, jointly awarded by the WEF and consulting firm McKinsey, identifies advanced manufacturing models that excel in productivity, supply chain resilience, sustainability, talent development, and customer-centricity. To date, 201 factories globally have received the recognition, with over 40% based in China. Tongwei Solar Meishan’s inclusion affirms its pioneering efforts in intelligent manufacturing while providing a replicable model for global PV producers.

Tongwei’s Meishan facility has integrated more than 50 applications aligned with the Fourth Industrial Revolution (4IR), leveraging cutting-edge technologies to enhance efficiency, stability, and sustainability. Key innovations include large-scale data analytics to optimize solar cell efficiency, deep learning for automated screen printing adjustments, convolutional and deep neural network-driven coating optimization, generative AI for equipment maintenance, and AI-powered closed-loop quality management systems.

These initiatives have yielded substantial performance gains. The company reports a 12% increase in photoelectric conversion efficiency, a 41% reduction in defect rates, a 37% cut in conversion costs, and a 33% reduction in CO₂ emissions. By deploying AI and digital intelligence across its production lines, Tongwei Solar has strengthened its competitive edge in the fiercely contested solar cell market.

The world’s first 'Lighthouse Factory' in the field of photovoltaic cell manufacturing: Tongwei Solar Meishan Company

Beyond operational improvements, Tongwei Solar has applied digital technologies to create a comprehensive manufacturing ecosystem. The company integrates industrial internet, big data, and AI models to build closed-loop capabilities spanning perception, decision-making, and execution. This system enhances reliability, ensures timely delivery, and reduces lifecycle costs, enabling the factory to provide stable and verifiable value to customers.

Tongwei Solar’s achievements come amid a broader global push toward high-end, intelligent, and green manufacturing. The convergence of AI, big data, and digital intelligence with PV production is accelerating the transition from conventional manufacturing to smart manufacturing, supporting global decarbonization and sustainable energy objectives.

The Meishan facility’s recognition as a Lighthouse Factory is also a testament to Tongwei’s long-standing industry leadership. Under Chairman Liu Hanyuan, the company has cultivated the PV sector for over a decade, establishing itself as a global leader in high-purity polysilicon and high-efficiency solar cells. In 2025, Tongwei secured its place on the Fortune Global 500 list for the third consecutive year, becoming the only company in the PV industry to achieve this milestone, with a brand value exceeding 250 billion yuan.

Sustainability remains a core focus for Tongwei. The company is a gold member of the RE100 initiative and has participated in five consecutive United Nations Climate Change Conferences. Tongwei has received top-tier ESG ratings, as well as awards from the British Standards Institution recognizing its contributions to sustainable development and standard-setting.

From building the first Industry 4.0 high-efficiency battery production line to establishing the PV industry’s first 5G application base, Tongwei Solar has consistently set benchmarks in intelligent manufacturing. The Meishan Lighthouse Factory demonstrates the company’s ability to combine advanced digital technologies, low-carbon practices, and operational excellence, providing a model for smart and sustainable PV production worldwide.

更多精彩内容,关注钛媒体微信号(ID:taimeiti),或者下载钛媒体App